How do we tell the differences of the tempered glass screen protectors from different suppliers?

— LAB TEST INDEXES

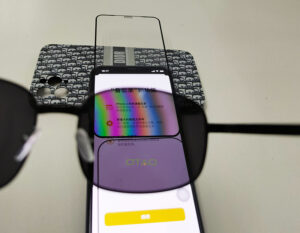

As a leading professional manufacturer, they will establish the labs for R&D and QC. OTAO had established 2 labs, assembled 20+ test grammas with precise devices, the real data of the test will help us control each procedure and quality of final production. The test data is better than any beautiful words.

- FALLING BALL TEST

It will be helpful to test the stress and anti-hit of tempered glass. If the stress is not enough, It means the tempered glass cannot bear the pressure and cannot protect the mobile display screen when one item falls to your mobile.

How to decide the stress value? tempering time and the quality of tempering liquid. Most suppliers will show the tempering time around 4-6h, and quality tempering liquid. In fact, they will short the time 1-2h, and over the recycle times of liquid usage, for improving the production capacity and reduce the sales price.

- WATER DROPLET ANGLE TEST

Water droplet angle is testing the AF coating. the AF coating will decide the smooth, anti-fingerprint performance of tempered glasses.

The good quality AF coating oil is being sprayed on the surface of tempered glass, 4-5 water droplets will be released on the surface, and test the angle of water droplet and glass. The bigger the angle is, the better the AF coating is.

- ABRASION TEST

What is an Abrasion test? why do we need it?

Abrasion test is simulating finger touch and friction in daily life. We will use the 1×1 steel wool, under 1 kg pressure, to rub 2000 / 3000/ 5000 turn-round. After finishing, we will test the angle of a water droplet, to test the lasting of AF coating. The bigger the angle is, the better the AF coating is.

Some suppliers will use the 2×2 steel wool or reduce the rubbing times to 1000, or 500 turn-round as 1000 times. It means that lower standard and lower price.

The poor-quality AF oil will bring the bigger angle before abrasion, but with higher criteria of abrasion test, the angle will go bad.

- ANOTHER test programs

Transmittance test

Edge press test

9H hardness test

Temperature and humidity test

Salt spray test

Adhesive test

Anti-oil test

Bending test

if you want to learn more about our test program, please contact with our sales.

Hence, when we select the suppliers, we should confirm

- The supplier has all testing programs and devices or not,

- How to do their test, what is their standard

- What is the data of test results

- The random sample test in each bulk order is acceptable

- Third-party to do the test is acceptable

So, what is your OTAO test result?

OTAO, as a professional supplier since 2011, had established several quality criteria with test indexes for reaching the client’s economic or mid-hi ends requirement. Please contact with OTAO Team for more detail, Contact@otao.biz